Why Top Cement Manufacturers Are Rushing To Meet Wastewater Compliance - And What You’ll Miss if You Don’t

Executive Summary

The cement industry in India faces stringent wastewater compliance regulations that require comprehensive understanding and implementation of best practices. With the Central Pollution Control Board (CPCB) enforcing strict discharge standards and the National Green Tribunal (NGT) increasing oversight, cement manufacturers must prioritize environmental compliance to maintain operational licenses and avoid penalties.

Understanding the Regulatory Landscape

Key Regulatory Framework

India's wastewater management regulations for the cement industry are governed by multiple legislative acts and enforcement bodies. The Water (Prevention and Control of Pollution) Act, 1974 serves as the foundational legislation, establishing the CPCB and State Pollution Control Boards (SPCBs) as primary enforcement agencies.

The regulatory framework includes:

Central Pollution Control Board (CPCB) - Sets nationwide effluent standards and technical guidelines

State Pollution Control Boards (SPCBs) - Enforce compliance at state level with region-specific adaptations

National Green Tribunal (NGT) - Issues directives and enforces penalties for violations

Recent Regulatory Updates

The 2024 Liquid Waste Management Rules introduced by the Ministry of Environment, Forest and Climate Change mark a significant evolution in wastewater regulations. These rules mandate:

Extended User Responsibility (EUR) framework for bulk water consumers

Initial reuse targets of 20% for 2027-28, rising to 50% by 2030-31

Rigorous compliance framework with monthly reporting requirements to SPCBs

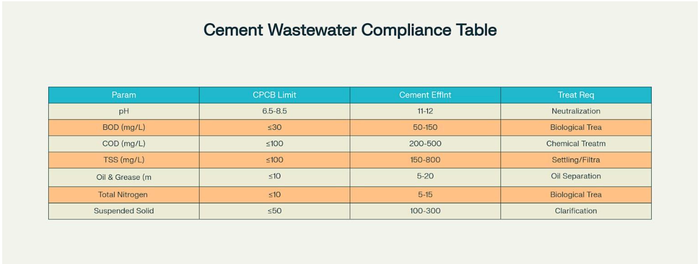

Compliance Table

Wastewater Parameters and CPCB Compliance Standards for Cement Industry

Wastewater Parameters and Compliance Standards

Critical Parameters for Cement Industry

Cement plants must monitor and control several key wastewater parameters to ensure regulatory compliance. The industry typically generates wastewater from cooling operations, equipment washing, and dust suppression activities [7] [8] .

Primary Compliance Parameters:

pH levels : CPCB standard range of 6.5-8.5, while cement effluent typically shows 11-12 due to alkaline dust

Biochemical Oxygen Demand (BOD) : Standard limit ≤30 mg/L

Chemical Oxygen Demand (COD) : Standard limit ≤100 mg/L

Total Suspended Solids (TSS) : Standard limit ≤100 mg/L

Oil and Grease : Standard limit ≤10 mg/L

Treatment Requirements

Each parameter requires specific treatment approaches:

pH Neutralization : Essential for alkaline cement effluent using acid dosing or CO₂ injection

Biological Treatment : Required for BOD and COD reduction

Physical Treatment : Settling tanks and clarifiers for TSS removal

Chemical Treatment : Coagulation and flocculation for fine particle removal

Best Practices Implementation in Cement Industry

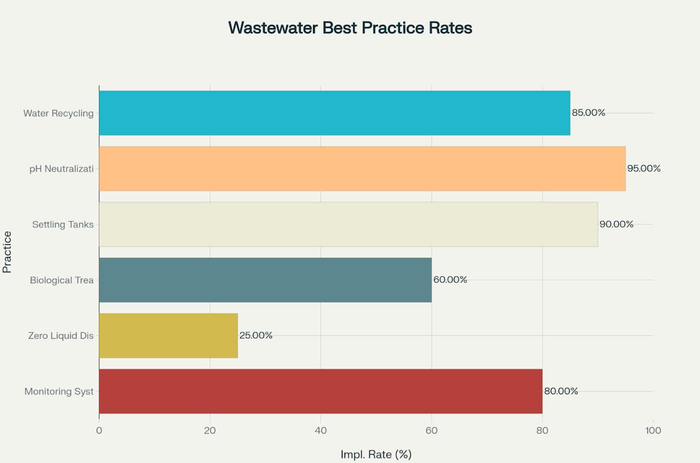

Wastewater Best Practice Rates

Implementation Rates of Wastewater Treatment Best Practices in Cement Industry

Water Recycling and Reuse

The Indian cement industry has made significant progress in water management, with 99% of installed capacity using dry process manufacturing to minimize water consumption. Leading companies like UltraTech have implemented comprehensive water conservation strategies:

Rainwater harvesting : 85 lakh cubic metres harvested at Vikram Cement Works in FY20

Zero-water discharge policy across all facilities

Concrete recycling technology : UltraTech saved 100 million litres through 'baton wash' technology

Zero Liquid Discharge (ZLD) Systems

ZLD technology represents the most advanced approach to wastewater management, achieving complete water recovery with only solid waste for disposal ] . Implementation involves:

Pre-treatment : Screening and pH adjustment

Advanced Treatment : Reverse osmosis, nanofiltration, electrodialysis

Concentration and Evaporation : Thermal processes for water recovery

Solid Waste Management : Appropriate disposal of concentrated residues

Monitoring and Control Systems

Effective compliance requires robust monitoring systems with:

Continuous monitoring of effluent parameters

SCADA systems for automated control

Regular sampling and testing as per SPCB requirements

Data logging and reporting for regulatory compliance

Compliance Costs and Implementation Timeline

Investment Requirements

Wastewater treatment infrastructure requires significant capital investment across different treatment levels:

Primary Treatment : ₹0.5-2.0 crores (3-6 months implementation)

Secondary Treatment : ₹2.0-5.0 crores (6-12 months implementation)

Tertiary Treatment : ₹3.0-8.0 crores (12-18 months implementation)

Zero Liquid Discharge : ₹10.0-25.0 crores (18-36 months implementation)[Based on industry data]

Return on Investment

Despite high initial costs, proper wastewater management delivers:

Regulatory compliance avoiding penalties and shutdowns

Water cost savings through recycling and reuse

Environmental benefits supporting sustainability goals

Operational efficiency through process optimization

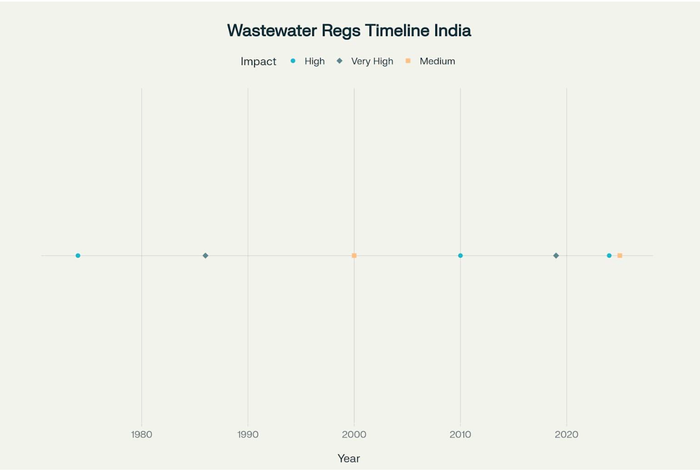

Evolution of Regulatory Environment

Wastewater Regulation Timeline

Evolution of Wastewater Regulations for Cement Industry in India (1974-2025)

Historical Development

The regulatory landscape has evolved significantly since 1974, with major milestones including:

1974 : Water (Prevention and Control of Pollution) Act established foundation

1986 : Environment Protection Act expanded regulatory scope

2019 : NGT amended sewage treatment standards

2024 : Liquid Waste Management Rules introduced comprehensive framework

2025 : Enhanced monitoring requirements implemented

Future Regulatory Trends

Emerging trends indicate:

Stricter discharge standards with lower permissible limits

Mandatory ZLD implementation for water-stressed regions

Digital monitoring requirements with real-time data transmission

Extended producer responsibility for water lifecycle management

Carbon footprint integration linking water and climate compliance

Case Studies: Successful Implementations

BlueDrop Project Overview

Deccan Cement Project

Client: Deccan Cements Limited (DCL), established in 1979.

Objective: Sustainable wastewater management for industrial & residential effluent.

Location: Bhavanipuram, Hyderabad, Telangana.

System Commissioned: January 2021, operational to present.

Technology: Aerated Vertical-Flow Constructed Wetlands (Natural Treatment System).

Capacity: 1.2 MLD (million liters/day) .

Technology Highlights

Artificial Aeration: Boosts oxygen availability, accelerates pollutant breakdown.

Performance:

BOD removal improved 10x ; TN/TP removal 2–4x vs passive systems.

Land Efficiency: Uses 1/5th less land than conventional wetlands .

Design & Process

Primary Treatment: Bar screening → equalization → anaerobic chambers.

Secondary Treatment:

Two constructed wetland units (1000 m² each, 1.8 m depth).

Layers of gravel, plant roots, microbial communities for nutrient removal.

Water Reuse: Treated water recycled for cement operations, dust suppression, landscaping .

Treatment Performance

Influent vs Effluent (Major Reductions):

BOD: 274 mg/L → 9.8 mg/L ( 96.4% reduction ).

COD: 505 mg/L → 58.6 mg/L.

TSS: 620 mg/L → 45.6 mg/L.

Total Nitrogen: 73.4 mg/L → 10.6 mg/L.

Overall Organic Removal Efficiency: 95–96% .

Nutrient Removal

TN Reduction: 87% via nitrification-denitrification.

Phosphorus Reduction: 86.5%, due to phosphate-accumulating microbes .

Cost-Benefit Analysis

Total Cost: ₹6.12 crore (CAPEX + OPEX).

Benefit-Cost Ratio (BCR): 7.61 – highly profitable.

Payback: 1.89 years (less than 2 years).

Economic Viability: Significant ROI driven by water reuse and compliance .

Co-Benefits

Low energy consumption & carbon footprint.

Silent, odor-free operation.

Sludge-free and simple maintenance.

Long system life with variable load handling.

Technology Solutions and Innovations

Advanced Treatment Technologies

Modern cement plants employ multiple treatment technologies:

Membrane bioreactors (MBR) for high-quality effluent production

Moving bed bioreactors (MBBR) for compact biological treatment

Activated sludge processes for large-scale operations

Advanced oxidation processes for recalcitrant pollutants

Digital Monitoring Solutions

Industry 4.0 technologies enhance compliance through:

IoT sensors for real-time parameter monitoring

AI-driven predictive analytics for treatment optimization

Blockchain for transparent compliance reporting

Remote monitoring systems reducing operational costs

Environmental Impact and Sustainability

Carbon Footprint Considerations

Wastewater treatment in cement industry intersects with climate goals:

Energy consumption in treatment processes affects carbon footprint

Water recycling reduces pressure on freshwater resources

ZLD systems support circular economy principles

Renewable energy integration in treatment plants reduces emissions

Ecosystem Protection

Proper wastewater management protects:

Surface water bodies from industrial contamination

Groundwater aquifers from infiltration of pollutants

Soil quality in surrounding agricultural areas

Biodiversity in downstream ecosystems

Implementation Roadmap for Cement Plants

Phase 1: Assessment and Planning (Months 1-3)

Conduct comprehensive wastewater audit

Identify compliance gaps against CPCB standards

Develop treatment technology selection criteria

Prepare regulatory approval applications

Phase 2: Infrastructure Development (Months 4-18)

Install primary and secondary treatment systems

Implement monitoring and control systems

Train operational staff on new procedures

Establish quality assurance protocols

Phase 3: Advanced Systems (Months 19-36)

Deploy tertiary treatment or ZLD systems

Integrate digital monitoring solutions

Optimize treatment processes for efficiency

Achieve full regulatory compliance certification

Phase 4: Continuous Improvement (Ongoing)

Regular system audits and upgrades

Technology optimization for cost reduction

Sustainability reporting and transparency

Industry best practice sharing

Conclusion

Compliance in wastewater management for India's cement industry requires a comprehensive approach combining regulatory understanding, nature based solutions, technological implementation, and operational excellence . With evolving regulations and increasing environmental scrutiny, cement manufacturers must proactively invest in advanced treatment technologies and robust monitoring systems.

The industry's transition toward water-positive operations through recycling, reuse, and zero liquid discharge systems demonstrates the potential for sustainable growth. Success depends on strategic planning, stakeholder engagement, and continuous adaptation to regulatory changes.

As the cement industry continues to grow with India's infrastructure development, maintaining environmental compliance while optimizing operational efficiency will determine long-term competitiveness and sustainability. Companies that embrace advanced wastewater management practices today will be better positioned for future regulatory requirements and market demands.

The integration of digital technologies, circular economy principles, and community engagement creates opportunities for cement manufacturers to transform wastewater management from a compliance burden into a competitive advantage, supporting India's vision of sustainable industrial development. BlueDrop Waters is uniquely positioned to help implement effective wastewater and effluent management strategies with expertise in all three areas. Reach out to get a free compliance audit.

⁂

Sources:

https://aquamech.co.in/industrial-wastewater-treatment-compliance-in-india/

https://susbio.in/government-standards-and-guidelines-for-sewage-treatment-plants-stps-in-india-2025-expert-guide/

https://www.epa.gov/sites/default/files/2018-07/documents/cement_mfg_dd_1974.pdf

https://www.linkedin.com/pulse/exploring-indias-legal-framework-industrial-4z83f

https://www.hecspstp.com/regulations-for-sewage-treatment-plants-in-india/

https://www.epa.gov/eg/cement-manufacturing-effluent-guidelines

https://www.downtoearth.org.in/water/there-are-challenges-and-opportunities-in-indias-2024-liquid-waste-management-rules

https://www.pib.gov.in/PressReleaseIframePage.aspx?PRID=1796222

https://www.nexi.go.jp/en/environment/pdf/ins_kankyou10e.pdf

https://www.netsolwater.com/how-does-government-policy-and-regulation-shape-wastewater-treatment-practices-in-indian-industries.php?blog=5695

https://www.ppsthane.com/blog/cpcb-wastewater-discharge-standards

https://www.holcim.com/sites/holcim/files/documents/lafargeholcim_cement_environmental_directive_revison_2020.pdf

https://timesofindia.indiatimes.com/city/chandigarh/ngt-panel-spots-green-compliance-gaps-at-adani-group-cement-plant/articleshow/118095507.cms

https://www.netsolwater.com/cpcb-guidelines-for-cement-industry.php?blog=4181

https://www.ecomena.org/environment-mena-cement/

https://www.cpcb.nic.in/uploads/Projects/Hadzardous-Waste/Latest_51_Latest_51_GUIDELINES-ON_CO-ProcessinginCement.pdf

https://cpcb.nic.in/generalstandards.pdf

https://www.sciencedirect.com/science/article/abs/pii/S2352710223022581

https://www.taxtmi.com/article/detailed?id=14127

https://cpcb.nic.in/effluent-emission/

https://www.oemupdate.com/technology/water-treatment-for-cement-plant/

https://www.tespl.com/projects/water-conservation-and-recycling/cement-and-steel-plants.php

https://pmc.ncbi.nlm.nih.gov/articles/PMC9477945/

https://www.getchemready.com/water-facts/concrete-wastewater-treatment/

https://www.saltworkstech.com/articles/what-is-zero-liquid-discharge-why-is-it-important/

https://www.internationaljournalcorner.com/index.php/ijird_ojs/article/download/135524/94648/326076

https://samcotech.com/solutions/zero-liquid-discharge/

https://www.ncbindia.com/environmental-management.php

https://sensorex.com/concrete-waste-disposal-managing-wastewater/

https://canadianclear.com/zero-liquid-discharge.html