Innovation is rapidly transforming wastewater management in the cement industry, enabling plants to enhance sustainability, reduce water use, and close critical resource loops.

The Need for Water Optimization in Cement

Cement and concrete production are water-intensive, driving the sector toward more efficient systems and alternative water sources. With global water scarcity and mounting regulatory requirements, innovation is not just a choice—it’s a necessity.

Breakthrough Technologies and Practices

Advanced Admixtures for Water Reduction

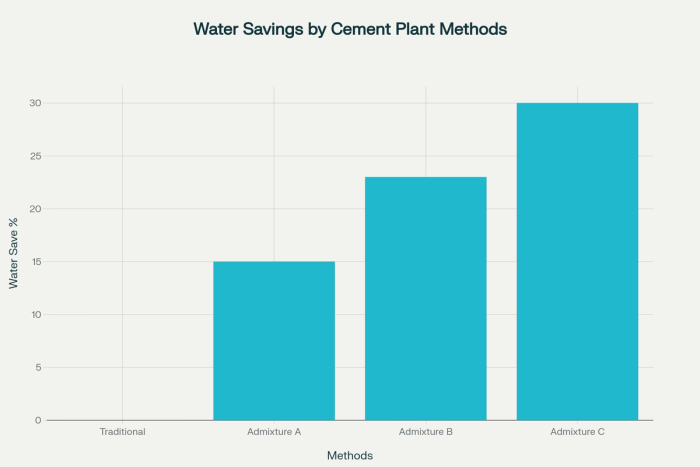

Modern chemical admixtures—such as superplasticizers—cut water use substantially during concrete mixing. These innovations optimize workability while lowering water-to-cement ratios, strengthening the final product and enhancing sustainability. Select admixtures can cut water needs by up to 30% compared to traditional methods.

The cement industry is embracing a new era of sustainable water management, powered by chemical innovation, advanced purification, and circular economy strategies. The result: robust compliance, reduced environmental impact, and a strong narrative for green construction in the future.

water savings by cement plant methods

Zero Liquid Discharge (ZLD) and Onsite Recycling

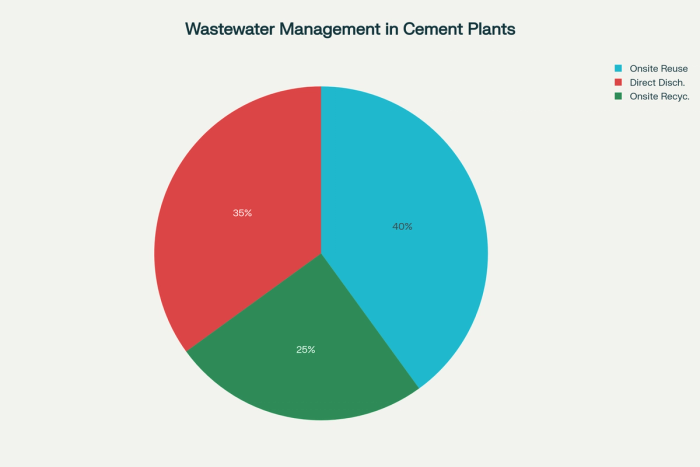

A rising trend is the deployment of ZLD systems, which recycle nearly all water used, leaving zero liquid waste for discharge. Innovative RO (reverse osmosis) and UV treatments deliver purified process water, reduce freshwater intake, and contribute to regulatory compliance and environmental stewardship. [1]

Wastewater Management Approaches in Cement Plants

Co-Processing of Biological Sludge

Co-processing biological sludge from municipal and industrial wastewater in cement kilns transforms a disposal problem into a resource recovery solution. High kiln temperatures destroy pathogens and recover minerals and energy from waste, exemplifying the circular economy vision. [2]

Emerging Bio- and Tech-Driven Solutions

Innovators have introduced biofilters using worms and microbes, high-efficiency nutrient removal with algae, and phosphorus-capturing pellets. These technologies both clean challenging waste streams and often generate valuable byproducts such as nutrient-rich fertilizers, reducing greenhouse gas emissions and operational costs. [4]

The Frontiers of Innovation in Cement Industry Wastewater Management

Wastewater management is at the heart of the cement industry’s transformation towards sustainability. New technologies are reshaping how plants treat, reuse, and recover resources, supporting environmental compliance and operational resilience.

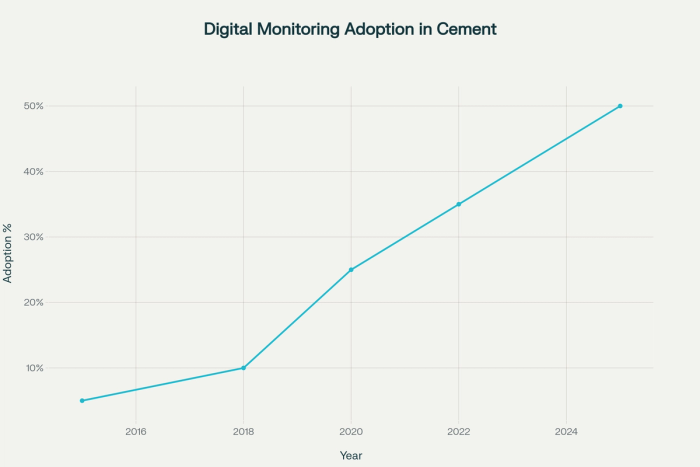

1. Digitalization: Smart Monitoring and AI Integration

Digitally enabled wastewater systems employ sensors, cloud platforms, and IoT for real-time tracking of water quality, flows, and critical plant KPIs. Artificial intelligence (AI) optimizes process parameters, enabling predictive maintenance and regulatory compliance.

Remote dashboards allow facility managers to track trends, pinpoint upsets, and optimize reagent dosing, even from mobile devices.

Adoption of digital controls in cement wastewater management rose from just 5% in 2015 to 50% in 2025, reflecting rapid industry transformation.

Digital Innovation Adoption in Cement Wastewater Management (2015-2025)

Digital Innovation Adoption in Cement Wastewater Management (2015-2025)

2. Advanced Biological and Bioelectrochemical Treatment

Biological approaches, like BioFiltro’s worm-microbe ecosystem, rapidly break down organic contaminants, generating beneficial worm castings for agriculture and slashing greenhouse gas emissions by up to 91%.

BioElectrochemical Treatment Technology (BETT®) uses bacteria that produce electric signals as they metabolize wastewater, providing both treatment and direct monitoring in a single system.

3. Co-Processing and Resource Recovery in Cement Kilns

Biological sludge from municipal and industrial wastewater is co-processed in cement kilns, destroying pathogens and recovering embedded minerals and energy.

This approach diverts tons of waste from landfill, yields alternative fuels, and incorporates minerals into cement products, embodying true circular economy principles.

4. Membrane Innovations and Additive Manufacturing

Novel membranes with engineered pore structures, created using advanced materials and additive manufacturing, offer tight contaminant removal with less fouling and greater energy efficiency.

These technologies are especially suitable for handling high-strength industrial wastewater with challenging chemical profiles.

5. Nutrient and Pollutant Capture

Algae-based treatment systems absorb nitrogen and phosphorus from wastewater, converting the resulting biomass into slow-release fertilizers, creating economic incentives to adopt best practices.

Water Warriors’ pellet-based removal technology captures phosphates, curbing toxic algal blooms and boosting environmental safety.

6. Supercritical Water Oxidation (SCWO) and PFAS Removal

Supercritical Water Oxidation destroys persistent contaminants (e.g., PFAS) and transforms complex organic waste into energy, allowing cement plants to safely deal with incoming mixed waste streams.

PFAS, ammonia, BOD, and COD can all be targeted in advanced reactors, keeping cement effluent safe for discharge or reuse.

7. Circular Economy Integration

Plants increasingly view waste as a resource, recovering phosphorus, nitrogen, and energy from wastewater streams, reducing reliance on virgin raw materials and cutting emissions.

Co-processing sewage sludge and byproduct integration enhance both sustainability and product quality, supporting ESG goals.

8. Data-Driven Compliance and Predictive Maintenance

Real-time data analytics and digital twins allow plants to instantly respond to changes in influent quality, optimize chemical dosing, and prevent costly equipment failures or permit breaches.

Data Snapshot: Cement Wastewater Flows

On average, innovative plants now reuse or recycle over 65% of their water, dramatically reducing environmental footprints—compared to much higher discharge rates in conventional setups.

Advanced admixtures alone can reduce water use by up to 30%, while ZLD systems help some plants reach near 100% recycling.

Case Study Insights

Plants deploying admixture technology and advanced recycling have cut annual water consumption by millions of liters, lowered treatment costs, and enhanced durability of finished concrete. [3]

Kiln co-processing of sludge in India and Europe has diverted tens of thousands of tons of waste from landfills, converting it into energy and new raw material inputs for cement production. [2]

Conclusion

The cement industry is embracing a new era of sustainable water management, powered by chemical innovation, advanced purification, and circular economy strategies. The result: robust compliance, reduced environmental impact, and a strong narrative for green construction in the future. [4] [1] [2] [3]

Sources

https://www.aquafilsep.com/cement-industry.php

https://insights.spans.co.in/the-role-of-cement-plants-in-biological-sludge-disposal-cltr6qrug000sortfu6ernedu/

https://cefic.org/case-study/reducing-water-use-in-concrete-production/

https://aquacycl.com/blog/13-new-technologies-that-are-changing-the-wastewater-treatment-landscape/

https://gccassociation.org/wp-content/uploads/2019/03/GCCA_Guidelines_Water-v0.pdf

https://www.sciencedirect.com/science/article/abs/pii/S2352710223022581

https://www.waterandwastewater.com/concrete-wastewater-treatment-plant/

https://www.epa.gov/sites/production/files/2018-07/documents/cement_mfg_dd_1974.pdf

https://www.oemupdate.com/technology/water-treatment-for-cement-plant/

https://www.vogelsang.info/en-in/segments/wastewater/case-studies

https://www.icontrolpollution.com/articles/physico-chemical-analysis-of-waste-water-from-cement-units-.php?aid=45440